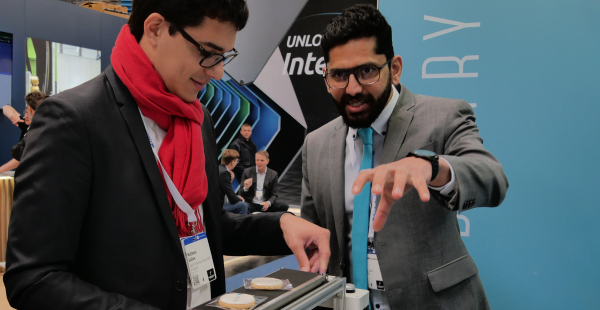

All kinds of tasks

Manage all kinds of task on a single platform, from simple To Dos to advanced interactive work instructions and forms.

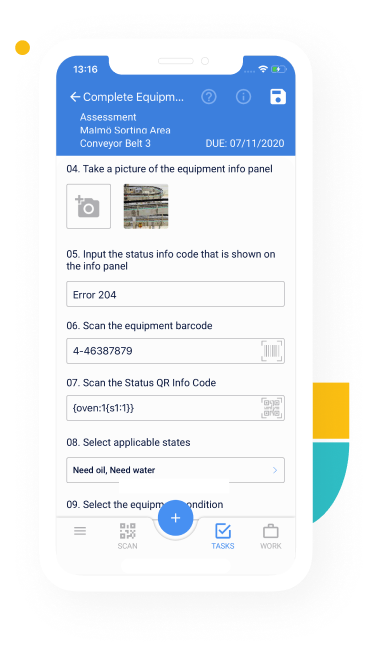

Smart Forms for the shop floor

Operators, engineers and other users collect information all day long with audits, inspections and assessments. Smart Forms supports numerous form types, automates results and provides analytics.

- Easy-to-use; no training required

- 16 different question types

- Unlimited configurable templates

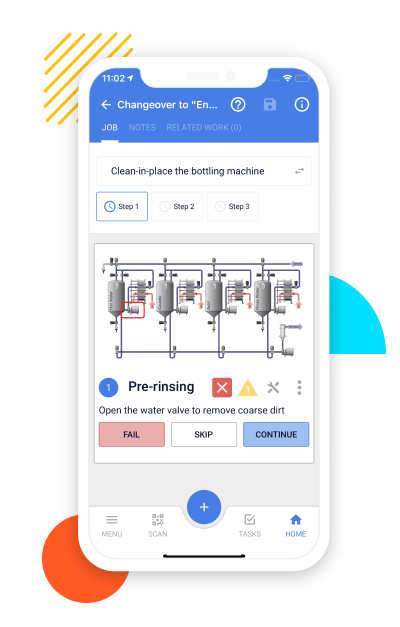

Digital work instructions for operators

Provide operators easy access to Standard Operating Procedures (SOPs), manuals and more—straight from their mobile devices.

- Step-by-step instructions

- Interactive data collection

- Standardize work & perfect execution

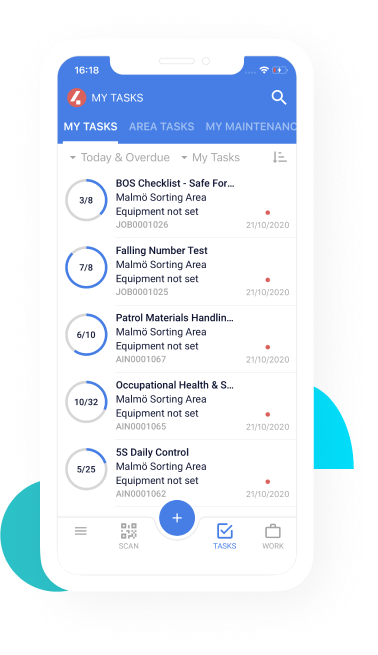

Plan and track tasks

There are countless tasks on the shop floor—from countermeasures and continuous improvement tasks to planned repetitive tasks. Our manufacturing Task Management software allows any task to be created, tracked, executed and analyzed from an easy-to-use mobile interface.

- Plan tasks across all production areas

- Schedule repetitive tasks and plan ahead

- Work from one task list that contains all daily tasks

Trusted by our customers and partners

Maturity Matrix

Check out what your plant task management maturity is by using our maturity matrix.

Download the pdf or request a report for your business for free.

Task Management is an integral part of the 4Industry platform, benefiting operators and factories in many ways.

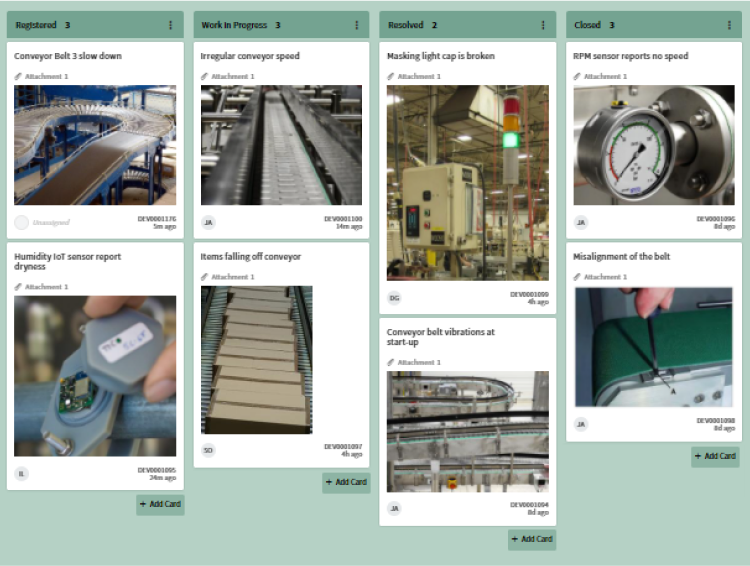

Visualize any task

Manage defect, inspection, improvement, audit and other tasks with easy-to-use Kanban style boards.

- Digital overview of all shop floor tasks

- Smooth collaboration during shift handover meetings

- Prioritize and assign the right daily tasks

Making task management easy for everybody

A unified task interface across all platform features makes the lives of your operators so much easier!