The platform for operational excellence

Achieve true world-class manufacturing by connecting operators, machines and data with a highly customizable, mobile-enabled Connected Worker Platform.

ServiceNow Announces Acquisition of 4Industry to Drive Innovation for Smart Industrial Environments and Connected Workers

Don’t take our word for it. Take theirs.

Find your use case

Discover our platform features

Smart Forms

Knowledge Management

Internet of Things

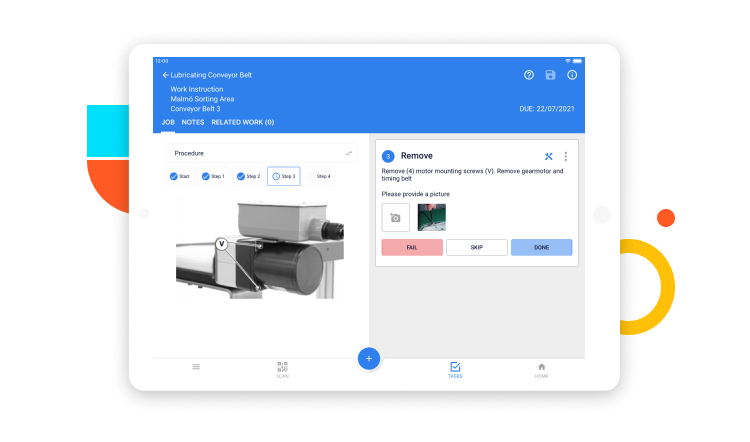

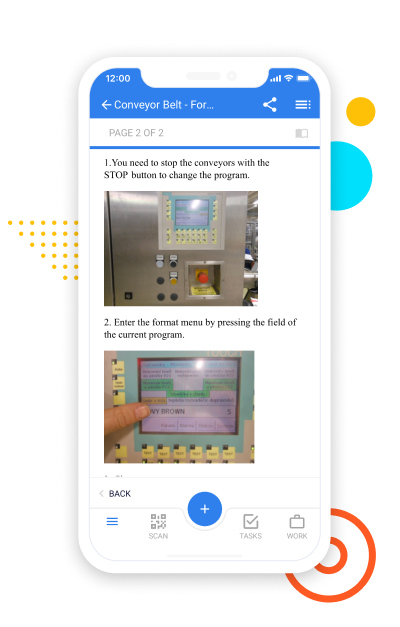

Digital Work Instructions

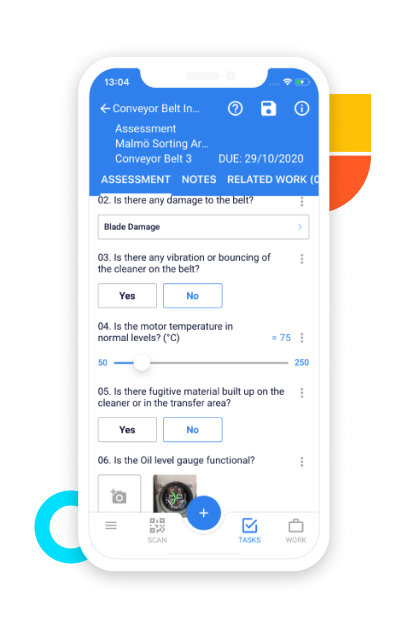

Smart Forms

Transform into a paperless factory by digitizing your checklists, audits, assessments and other forms. Enable your operators to capture consistent data straight from the shop floor.

20+

Over 20 seamless integrations with manufacturing IT systems like MES, ERP, and SCADA.

<3m

Go from pilot to launch in less than 3 months.

99%

Built on ServiceNow, the 4Industry app has near-perfect uptime of 99%.

150+

150+ factories already use 4Industry worldwide.

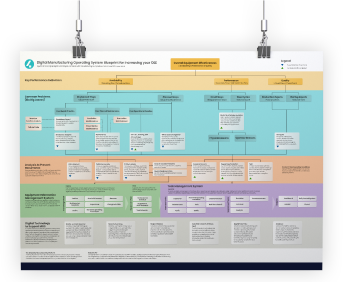

Increase your OEE with our free Connected Worker blueprint

This blueprint explains how a Connected Worker Platform (CWP), combined with digital technology and manufacturing best practices, can increase OEE in your plants.

Or get started with our knowledge articles

Increase your OEE

Discover how connected workers optimize operations and increase uptime to boost your OEE.

Connect your workers

Improve line performance, quality, and uptime by augmenting shop floor work with digital tech.

Improve continuously

Drive continuous improvement by allowing workers to capture, share, and optimize knowledge quickly and easily.